Bonded fabric is a fusion of materials that marries innovation with functionality. In this blog post, we'll delve into these versatile fibers, and explore how bonded fabrics revolutionize industries and elevate fabrics.

What is bonded fabric?

Bonded fabric refers to a type of material made by combining two or more different fabrics or materials through a bonding process. This process creates a single, composite material that leverages the properties of each individual component. The bonding is typically achieved using adhesives, heat, pressure, or a combination of these methods.

There are various methods for creating bonded fabric:

- Adhesive Bonding: This involves using adhesives or glues to bond fabrics together. The adhesive is applied to one or both surfaces and then heated or cured to create a durable bond.

- Heat Bonding: Heat bonding, also known as heat sealing, involves using heat and pressure to fuse fabrics together. This can be done through heat-activated adhesives or by melting the fibers of the fabrics to form a bond.

- Ultrasonic Bonding: This method uses high-frequency ultrasonic vibrations to bond fabrics together without the need for adhesives or stitching. The vibrations create localized heat, melting the fibers and forming a bond.

Bonded fabrics can combine a wide range of materials, such as different types of textiles, foams, films, or membranes. The resulting material often exhibits enhanced properties, such as improved strength, durability, water resistance, or insulation.

These fabrics find applications in various industries, including fashion, outdoor apparel, sportswear, automotive interiors, and home furnishings. In fashion, bonded fabrics are appreciated for their versatility, allowing designers to create innovative and structured garments while incorporating different textures and functionalities into clothing designs.

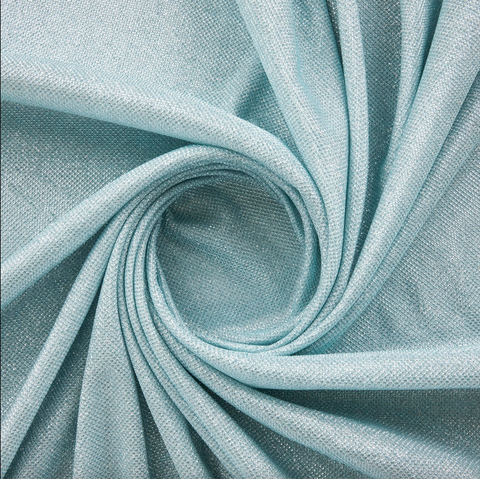

Zelouf Jianna Bonded Glitter Mesh

What are some examples of products made from bonded fabric?

Bonded fabrics find applications in various industries, resulting in a wide array of products. Here are some examples across different sectors:

- Outerwear and Apparel: Bonded fabrics are commonly used in outerwear and apparel for their versatility and functionality. They can be found in:

- Jackets and Coats: Weather-resistant jackets, insulated coats, and stylish outerwear often utilize bonded fabrics for their durability and weatherproof properties.

- Athletic Wear: Sportswear, workout gear, and activewear benefit from bonded fabrics that offer breathability, flexibility, and moisture-wicking capabilities.

- Accessories:

- Bags and Backpacks: Many high-quality bags, backpacks, and luggage items incorporate bonded fabrics for their strength, water resistance, and stylish appearance.

- Belts and Accessories: Some belts and accessories use bonded materials for their durability and ability to maintain shape and structure.

- Automotive Industry: Bonded fabrics are employed in vehicle interiors for their durability, comfort, and aesthetic appeal.

- Car Interiors: Seat covers, headliners, door panels, and other parts of car interiors often use bonded fabrics for their durability and ease of maintenance.

- Home Furnishings:

- Upholstery: Some furniture, especially in high-traffic areas, uses bonded fabrics for their resilience and ease of cleaning.

- Curtains and Drapes: Bonded fabrics can offer both style and functionality in curtains, providing insulation and light control.

- Industrial and Technical Applications:

- Medical Textiles: Some medical garments or protective wear use bonded fabrics for their protective and breathable qualities.

- Technical Textiles: Bonded fabrics are utilized in various technical applications, such as in construction, filtration systems, and industrial uses, due to their specialized properties like strength, water resistance, or insulation.

These examples showcase the diverse applications of bonded fabrics across different industries, highlighting their adaptability, durability, and versatility in creating a wide range of products.

What are some tips for working with bonded fabric?

Working with bonded fabric requires attention to certain techniques and considerations due to its composite nature and specific characteristics. Here are some tips for working with bonded fabrics:

- Use the Right Tools:

- Sharp Cutting Tools: Use sharp scissors or rotary cutters to prevent fraying or damaging the bonded layers.

- Proper Needles and Thread: Choose needles and threads suitable for the specific fabric types being bonded. For instance, consider using a ballpoint needle for knits or stretch fabrics.

- Test Before Sewing:

- Before starting your project, conduct tests on scraps of the bonded fabric to determine the appropriate stitching techniques, needle size, and tension settings for your sewing machine.

- Take Precautions While Pressing:

- Be cautious with pressing or ironing bonded fabrics. Use a pressing cloth or a low-heat setting to avoid damaging or melting the bonded layers.

- Some bonded fabrics might be heat-sensitive, so always test a small area before applying heat across the entire fabric.

- Seam Finishing:

- Consider finishing seams to prevent fraying or separation of the bonded layers. Techniques like serging, zigzag stitching, or using seam sealants can help reinforce seams.

- Handling and Cutting:

- Handle bonded fabric carefully to avoid separating the layers. Be mindful of the direction of the nap or pattern while cutting to ensure consistency in the final product.

- Use Compatible Adhesives:

- If working with adhesive-bonded fabrics, ensure that any additional adhesives used during the sewing process are compatible with the existing bonding to prevent weakening or separation.

- Pinning and Marking:

- Avoid pinning excessively on the bonded areas to prevent leaving permanent marks. Consider using clips or temporary fabric adhesive for holding pieces together during sewing.

- Finishing Touches:

- When finishing edges or hems, consider techniques that maintain the integrity of the bonded layers. Fold and stitch carefully to ensure a clean and durable finish.

- Read Manufacturer Instructions:

- Always refer to the manufacturer's instructions or guidelines specific to the bonded fabric you're using. They may provide valuable tips or precautions tailored to that particular material.

By following these tips and taking care when working with bonded fabrics, you can enhance the durability and appearance of your projects while making the most of the unique properties offered by these composite materials.